- Unit 13,Floor 5h, No 179, Orchid Building, East-Ferdows, Tehran, IRAN

- info@Armaantejarat.com

- 0098912021800

The difference between micronized and coated calcium carbonate

The difference between micronized and coated calcium carbonate

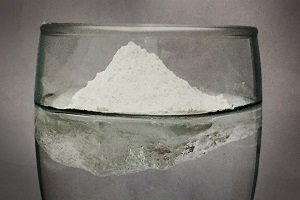

Calcium carbonate is a chemical compound with the formula CaCO3 and is present in the structure of various rocks, including limestone. This compound is found in nature in three different forms, aragonite, calcite, and vaterite. Micronized and coated calcium carbonate are the most widely used types of calcium carbonate in various industries. In this article from Arasang Alvand, we will introduce and discuss the differences between micronized and coated calcium carbonate. Stay with us until the end of this article for more information.

What is micronized calcium carbonate?

Micronized calcium carbonate or nano calcium carbonate is actually a type of calcium carbonate that has very small grains. This type of calcium carbonate is produced using special processes so that its particle size is in the micron (less than 75 microns) and even nanometer (less than 1 micron) range.

The characteristics of micronized calcium carbonate are different and unique due to its small particle size. These features include:

Highest absorption and rapid absorption: Due to its large surface area and high surface activity, micronized calcium carbonate has a higher absorption and rapid absorption capacity.

Homogeneous particle distribution: Micronized calcium carbonate particles are evenly and homogeneously distributed, which makes it easy and more efficient to use in various processes.

High solubility: Due to its small particle size and large surface area, micronized calcium carbonate has a high solubility in various media.

Physical and chemical effects: Micronized calcium carbonate can have a variety of physical and chemical effects, including color change, strength enhancement, pH control, and surface property adjustment.

Coated calcium carbonate is also a special type of calcium carbonate that is produced in powder form with shorter particle sizes. This type of calcium carbonate is usually available in larger meshes (above 75 microns) and has different applications in industries. Due to the different properties of micronized and coated calcium carbonate, each is used in its own specific applications.

What is coated calcium carbonate?

Coated calcium carbonate is a type of calcium carbonate coated with a layer of stearic acid, a type of fatty acid. Stearic acid has a long organic chain with an acidic end. The acidic part of this organic chain is attached to the polar surface of calcium carbonate, and then its long non-polar end is attached to the calcium carbonate particles. This acidic coating makes coated calcium carbonate hydrophobic, while regular calcium carbonate is hydrophilic.

Coated calcium carbonate with this acidic coating has important properties. These properties include low energy level, high hydrophobicity, low oil absorption, increased mechanical strength, creating a high-quality and bright surface, compatibility with organic environments, and a whiteness of at least 98% and a brightness of at least 96%. Also, coated calcium carbonate has a maximum moisture content of 0.2%.

Therefore, the use of coated calcium carbonate in some industries, such as polymer production, has many advantages due to the above-mentioned characteristics.

Differences and similarities between micronized calcium carbonate and coated

The main difference between micronized calcium carbonate and coated is the presence of a fatty acid coating in coated calcium carbonate. While micronized calcium carbonate does not have this coating. The stearic fatty acid used in coated calcium carbonate binds to the polar surface of calcium carbonate and then its long non-polar head is attached to the calcium carbonate particles. This acidic coating makes coated calcium carbonate hydrophobic and has low oil absorption.

In contrast, micronized calcium carbonate does not have this coating and is produced in the form of small and fine particles. These particles have micronized dimensions, which is why they are called micronized. Micronized calcium carbonate can be found in powder or granular form.

As for the similarities, both micronized and coated calcium carbonate are produced by grinding natural rocks containing calcium carbonate. Also, both of these materials can be used in different industries, but their applications may differ due to the different characteristics mentioned above.

Uses of Micronized and Coated Calcium Carbonate

Uses of micronized and coated calcium carbonate include the following:

Iron casting

Steel production

Papermaking

Livestock and poultry feed

Construction and road construction

Oil and gas well drilling

Edible and pharmaceutical lime production

Paint and adhesive industry

Cable and wire industry

Detergent and sanitary products industry

Tiles and ceramics

Coated calcium carbonate also has a variety of uses, including:

Plastics

Polymers

PVC profiles

Profile sheets

PVC pipes

Industrial paints

Filler primers

Anti-corrosion fillers

Construction and cement production

The uses of micronized and coated calcium carbonate in various industries show that each of them has its own characteristics and applications and is used depending on the needs of the products and production processes.

Buy Calcium Carbonate

It is better to buy micronized and coated calcium carbonate from reputable and well-known brands, because the quality of raw materials can have a significant impact on the quality of industrial products. You can place an order for calcium carbonate purchase from the Arasang Alvand website. This website provides all orders for micronized calcium carbonate and various types of calcium carbonate meshes.

Conclusion

Calcium carbonate mineral powder with a mesh size of 200 or smaller is considered micronized. Micronized size refers to the unit of measurement of micrometers. Finer particles have a higher price, because their production takes longer and the amount of product produced is lower. Calcium carbonate coated with fatty acids, which is

Coated calcium carbonate is well known. This coating prevents oil absorption and makes it hydrophobic. Micronized and coated calcium carbonate have many applications in various industries.

Similar Blog

The difference between micronized and coated calcium carbonate

Calcium carbonate is a chemical compound with the formula CaCO3 and is present in the structure of various rocks, including limestone. This compoun...

Solubility of calcium carbonate in water

Whether calcium carbonate dissolves in water is an important issue in the field of water chemistry and its impact on health and the environment. Calci...

Application of calcium carbonate in animal feed

Calcium plays a very important role in animal growth. This nutrient helps strengthen the bones of livestock and also improves the strength of eggs. Ca...